1,400 Miles in 350 Days, The Forgotten American Oil Pipeline That Crushed the Nazis In WWII

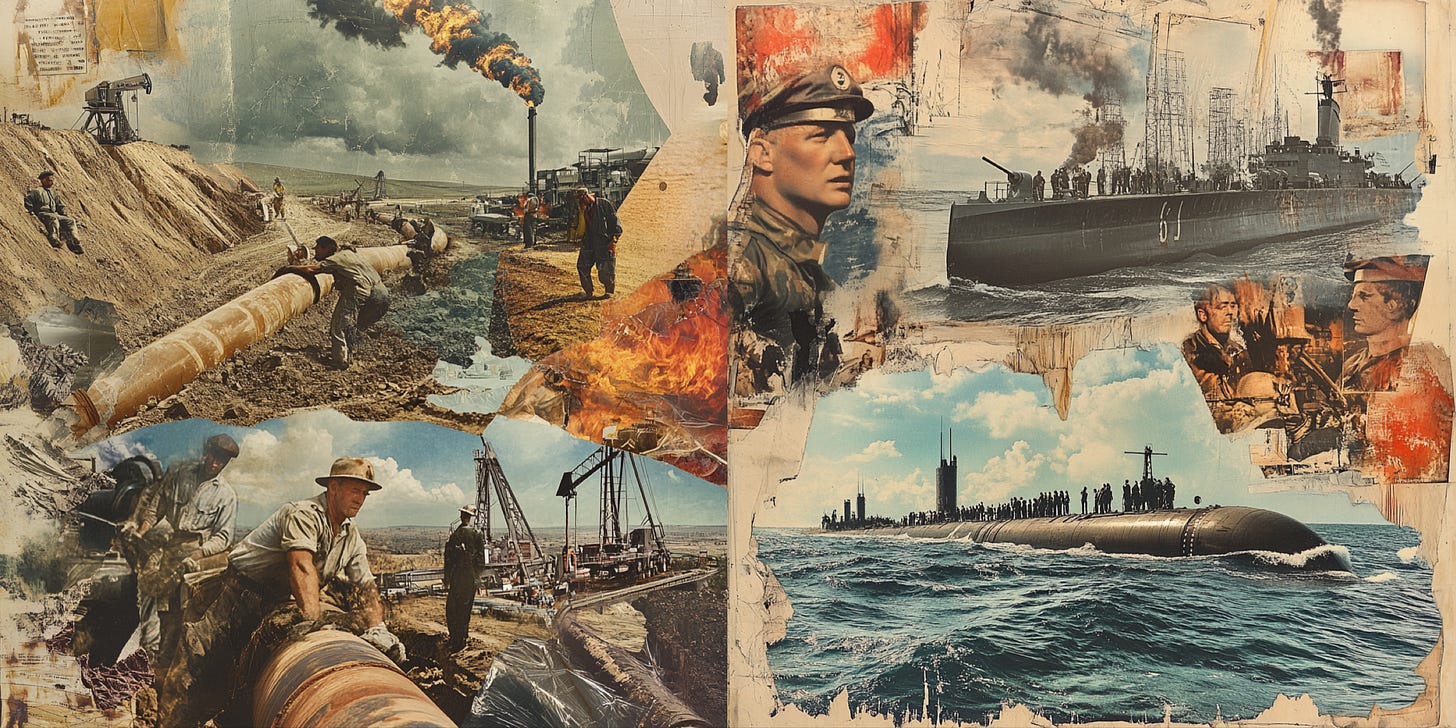

Buried beneath America’s soil lies the forgotten story of the War Emergency Pipeline Committee, 1,400 miles of steel laid in 350 days and the race against Nazi U-boats to save the free world.

“This industry can do a whole lot more, but we need some assistance to be able to get the infrastructure needed so that we can add more supply into this world.”

— EQT CEO Toby Rice, in a recent CNBC interview

As many of his peers have narrated over the last decade of post-shale boom, natural gas growth in the United States - Building infrastructure is hard. Whether you blame it on over regulation, globally competitive commodity markets, lack of industrial dominion in key industries (like Steelmaking, Turbomachinery fabrication, etc.) or the weaponization of state sponsored capital abroad – it is abundantly clear, America has regressed in its acumen of building big things, very fast.

But don’t get lost in the doom and gloom, recent herculean efforts by teams at Tesla, NVIDIA, and SpaceX have reinvigorated the country, and shown what determination and mission-oriented grit can yield. In a society of supercomputers in our pockets with artificial general intelligence on the cusp of being ubiquitous, we often fail to recognize the ugly bald spots within our utopia of innovation… Our ancestors were built different. The Manhattan Project. The Apollo Space Program. Freedom’s Forge. All of these historical efforts garner well deserved attention for their display of American resolve and masterclass execution of Public/Private Partnership in time of need. But the Big and Little Inch Pipeline stories don’t circulate the ether quite as often as these other efforts, and in 2025, few stories are as relevant for our current predicament.

The Pearl Harbor-esque attacks you may not have learned in school:

German U-Boats in the Gulf of Mexico.

December 7, 1941 – Pearl Harbor.

No education needed, one of the grimmest days in American history as Japanese forces bombed a US installation the Hawaiian Islands, killing over 2,000 Americans, and destroying billions of dollars in equipment including a half dozen aircraft carriers and over 200 planes. Given the significance of the attack and the subsequent entrance of the US Armed Forces into the arena of the second World War – the events of Pearl Harbor often overshadow other military activity in the Western Hemisphere around this time, in this case even closer to the mainland.

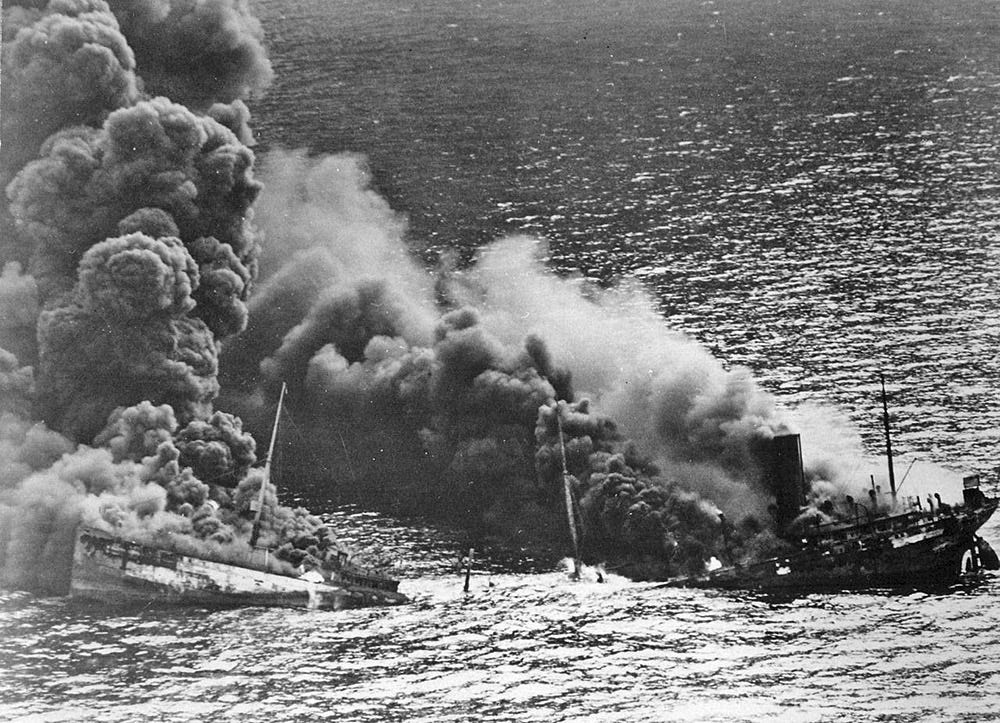

1942 – German U-boats in the Gulf of Mexico

In 1942, mere months after America’s entry to the Pacific and Western European theater, cargo ships began to face trouble within 50 miles of Louisiana shore in the Gulf of Mexico. According to reports by the Bureau of Ocean Energy Management, some 56 vessels including cargo ships, tankers, freight liners, and passenger ships were sunk in coastal waters by German Kriegsmarine U-boats.

It was clear that the Axis powers weren’t content to let the US intervene in the European theater, as the American people rallied to support the war effort in the form of military vehicles, firearms, munitions, rations, and most importantly – fuel. In the 1930’s and 1940’s, most of the nation’s oil came from patches in Oklahoma, Texas, and Louisiana – and most of the demand was in the industrialized Atlantic and New England corridor.

The solution of its time: ship fuels on the water around the peninsula of Florida into coastal import facilities in New York, New Jersey and Virginia. According to the inscription on the memorial of the Big Inch Pipeline, nearly 95% of crude oil that was delivered to refineries on East Coast was delivered by tanker.

This strategy became a problem for the US, its allies, and the war effort – and as Hitler, Mussolini, and the Axis forces pushed west into France and the UK, it was clear that the US would have to get creative to deliver fuel to the coast another way. And time was not on their side.

The Formation of the War Emergency Pipeline Committee:

How FDR set the stage for the greatest American project since Manifest Destiny.

In the late spring of 1942, the President of the United States, Franklin D. Roosevelt, convened a committee led by the Secretary of Interior, Harold Ickes, to discuss alternative measures to deliver crude oil from the patch in the American South to refineries and factories in the Midwest and New England, as a means to support the war effort across the pond. Their solution: build two pipelines to connect critical cross-continent supply chains. To put into perspective, this effort was undertaken 80+ years ago. 80 years ago. Eighty. Eight zero.

The Big Inch Pipeline

Returning our attention to the project, the project is best understood when parsed into two distinct efforts. The first being the Big Inch Pipeline, a 24” diameter pipeline stretching from Longview, TX through Illinois and terminating in Linden, NJ and Chester Junction, PA. This project at full maturity was over 1,200 miles long, with over 40 pumping stations and distribution facilities. The second effort of the project was the Little Inch Pipeline (not to be undersold by its name, our ancestors weren’t much for frivolities), a 20” diameter pipeline that ran from Beaumont, TX in parallel with the Big Inch into New England.

The Little Inch Pipeline stretched almost 1,500 miles (despite having smaller diameter, it stretched longer than its counterpart) with a half dozen additional pumping stations and topside equipment stations. The lines were designed to be capable of moving crude oil, gasoline, and a variety of refined products across the country to meet demand abroad in the industrialized Midwest and New England, as well as across the pond in the European war theater. The projects were built in climates ranging from scalding-hot Texas to the frigid, mountainous Poconos and required land clearing of 100 foot wide right of ways for 1,500~ miles, totaling nearly 40,000 acres. All this clearing was done with the earliest iterations of internal combustion engine heavy machinery, a far cry from the equipment Caterpillar or Komatsu make today.

Both pipeline efforts consisted of aligning heavy 40’ joints of steel pipe weighing tons per segment and welding them together repetitively. The workload required about 400,000 pipe joints to be laid in place and welded on each end, out in the elements and the required trenches had to be dug about 4 feet deep and 4 feet wide. These trenches between the two projects displaced nearly 10 million cubic yards of soil, not including the soil disturbance associated with the pumping stations and topside equipment facilities. The entirety of construction activity listed above was conducted with rudimentary heavy machinery, with Caterpillar ICE equipment in its infancy, a far cry from what they have in their catalogue today. And the most astonishing statistic of them all?

The War Emergency Pipeline project, the construction of the Big Inch and Little Inch Pipeline was completed from break ground to final weld, in just 350 days.

That’s over 1,000 joints of pipe laid and 2,000 large diameter welds per day, and 100+ acres cleared per day. In conditions ranging from 0⁰ F – 100⁰ F, across mountains and rivers (notably the Mississippi River), with no rest days or PTO days, in the 1940’s. Remember when I said our ancestors were built different?

In today’s climate of infrastructure development, a pipeline company today may wait 350 days between review sessions with regulators, with the average time to permit and receive FERC approval for an interstate pipeline project being 3-4 years (projects that are a fraction of the scale as the Big and Little Inch if I might add). Beyond that, developers are looking at years of procurement, design, local permitting efforts, land acquisition, construction, testing, and commissioning processes. Building a project like the War Emergency Pipeline in today’s environment would likely be considered near impossible by even our societies’ wildest dreamers.

State of Affairs

The US is Re-industrializing again, setting the stage in the image of 1941.

The creation of this article is not to bash the regulatory apparatus we are saddled with, or to suggest that Americans today are any less than the Americans of yesteryear – but to call attention to the resolve of human beings in responding to dire odds. When the odds are against the American people, we have a history of responding in miraculous ways. And one could argue we face similar industrial challenges today to our counterpart Americans of the 1940’s. Geopolitical tension is affecting our ability as a nation to control our supply chains and balance our free market in the face of national security. As China begins to curb exports on Graphite and Gallium, trade wars are underway from the United States v. everybody, Chinese continued flirtation with Taiwan over critical TSMC assets, and expanded Chinese and Russian reach in Africa and beyond – it is clear that America must take direct action in re-developing industrial capabilities that we have long taken for granted, and find new supply routes to ensure national security and abundance. Despite how tall of a task this is, recall our ancestors’ efforts in the war time effort of the 1940’s.

With this need to re-define American Industry, the Trump-Vance ticket spoke to the hearts and minds of many, as their “America First” stance and legacy engagement with technology, industry and infrastructure – gave the American people a horse to bet on that at face value, promoted the address of shortcomings listed in this article. Since being inaugurated, President Trump has taken action to re-industrialize including

public engagement with Greenland and Ukraine in pursuit of their strategic positioning and potential rare-earth element deposits,

announcement of the Stargate Project in collaboration with OpenAI, SoftBank, and Oracle to expand Artificial Intelligence infrastructure domestically,

creation of the Office of Shipbuilding, to catalyze the nation’s efforts to improve and expand shipyard infrastructure and shipbuilding capacity to compete with China and Russia,

curtailing supplies to the Ukraine War and jockeying for peace, in an effort to protect US stockpiles while re-supply efforts are under way,

strategic investment partnerships with Japan, Korea, UAE, and Saudi Arabia – totaling hundreds of billions of dollars of investment in US companies, and US onshoring efforts.

Our National Call to Action:

We have been here before as a nation, and we have the strategic blueprint to win again.

In an effort to be an honest broker of information, these announcements, along with Department of Government Efficiency (DOGE) cuts to government spending, caused a decline to global markets S&P, NASDAQ, and BTC at recent lows in March - April 2025.

As the market experiences a resurgence, it is clear that there are growing pains when it comes to re-industrialization, mega public-private partnerships, and grand visions for American industry – in the form of rising consumer prices and market stalling. But what are you willing to give up in exchange for ‘cheap stuff’? Is domesticating critical supply chains away from high-risk regions worth an impermanent rise in the cost of goods?

These questions are somewhat rhetorical, and obviously require assessment of several factors, but the thought exercise insists that we as a nation must call upon the spirit of our predecessors to take on herculean efforts to address our challenges rather than sweep them under the rug.

The news and political scene may paint a scary, insurmountable landscape of the US’s present situation, but we have a long history of combining mission oriented private industry, with the guidance of the public sector – to ensure that America and Americans continue to control their destiny as the voice of Freedom to the globe. Let the Big Inch Pipeline be an ode to American resolve and the potential for public-private partnership, in a time where re-industrialization is paramount. Americans have long solved big problems in record time. Now seems as good a time as ever to tap into our inherent collective spirit.

Here’s to the next generation of Industrialists and to the collective enterprising spirit of the West!

About the Author

Grant Brown is a proud Texan, bringing his experience in the energy industry to the tech world, as dynamics change in the production and delivery of society’s most valuable commodities. Grant is part of the investment team of 8090 Industries, an Industrial DeepTech Venture Firm looking to back the world’s most ambitious founders on the most daring of missions. Grant and the team at 8090 have backed companies like Oklo, Infinium, Exowatt, Quaise, Armada, Cemvita, Durin, and Karman Industries – among many others. The team targets generational founders, first principles thinking, and a savage appetite for execution. Prior to his entry to the Venture scene, Grant was a Pipeline Engineer at Williams Companies, working on some of the largest assets known to mankind and ensuring reliable, safe transport of natural gas and natural gas derivatives to communities and industries who needed them. From South Texas, to Southern Louisiana, to the Gulf of Mexico, to the Poconos – Grant worked boots on the ground building, maintaining, and optimizing pipeline systems for an ever-changing global energy market. As a professional who has seen infrastructure and scale at the highest level, Grant’s mission is to build the next generation of industrialists in the familiar image of existing industrial titans. Grant is a proud husband and father, and a proud follower of Jesus Christ. He and his family are based between Austin and Houston, TX.

Sources

https://heartoflouisiana.com/u-boats-in-the-gulf/

https://hnoc.org/publishing/first-draft/1942-german-submarines-brought-wwii-louisianas-shores

https://www.boem.gov/environment/world-war-ii-shipwrecks

https://www.tshaonline.org/handbook/entries/big-inch-and-little-big-inch

https://www.hmdb.org/m.asp?m=154609